Post Mould Installed

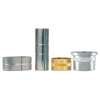

SPIROL manufactures several different styles of Post Mould Installed Compression Limiters for installation into the plastic component after the moulding process is complete. Installing Compression Limiters after the plastic has cooled typically results in the lowest total installed cost since there is no added cycle time associated with placing the Compression Limiters over core pins during the moulding process. Post mould installed Compression Limiters also eliminate any concern with damaging the mould due to improperly positioned components.

All SPIROL Split Seam Compression Limiters (CL220 Split Seam, CL200 Split Seam - Slim Profile, Series CL350 Split Seam - Heavy Wall, Series CL400 Split Seam - Oval) are to be post mould installed by pressing the Limiter into the hole after the moulding process is complete. The solid wall, knurled Compression Limiters (Series CL6000 & CL6100 Precision Machined Aluminium, Series CL8000 & CL8100 Precision Machined Brass and CL620 General Purpose Aluminium) can be installed either by pressing the Limiter into the hole or moulding the Limiter into the assembly.

SPIROL Standard Post Mould Compression Limiters include: The Series CL220 Split Seam, Series CL200 Split Seam - Slim Profile, Series CL350 Split Seam - Heavy Wall, Series CL400 Split Seam - Oval, Series CL6000, CL6100 & CL620 Aluminium and Series CL8000 & CL8100 Brass.

Application Engineering Assistance: If you would like assistance in selecting the proper Compression Limiter - including the recommended plastic thickness, hole size, and tolerance for your assembly, please Request Engineering Support! We are here to help!

Symmetrical (Round) Compression Limiters

Split Seam

The Series CL220 Compression Limiter is produced from high carbon steel and intended for post-mould installation. The spring force generated during installation provides self-retention in the assembly. The flexible diameter accommodates wide hole tolerances, and the gap is designed such that the parts will not interlock in the free state. Once installed, the CL220 provides a minimum clearance of 1mm around the bolt diameter to compensate for misalignment. The CL220 is the only standard Compression Limiter finished with a protective coating of ArmorGalv®, a zinc alloy thermal diffusion coating complimented with two sealers that provides 1000+ hours of salt spray protection for highly corrosive applications such as automotive, marine, mining and industrial manufacturing. Additional benefits of ArmorGalv® include no insignificant surfaces as the entire inner diameter (ID) of the Limiter receives full coating and protection. The CL220 is rated for use up to ISO Class 8.8 bolts. The CL220 offers the widest range of standard diameter and length combinations to accommodate a variety of application requirements.

Split Seam - Slim Profile

Similar to the Series CL220, the CL200 Slim Profile Compression Limiter has a smaller inner diameter (ID) after insertion and a reduced overall profile with less clearance around the bolt. Once installed, the CL200 provides a minimum clearance of 0.5mm as compared to the larger minimum clearance of 1mm provided by the CL220. The CL200 is rated for use up to ISO Class 8.8 bolts.

Split Seam - Heavy Wall

The CL350 was designed with a thicker wall for increased bearing surface when clamped against soft mating materials. Generous bolt clearance also aids in positional alignment when multiple Compression Limiters are used in an assembly. The CL350 is rated for use up to ISO Class 10.9 bolts.

Precision Machined Symmetrical Compression Limiters

Aluminium

The Series CL6000 is machined from 2024 aluminium as this grade provides the best combination of strength, corrosion resistance, machinability and cost. Additional advantages of aluminium are that it is lightweight (1/3 the weight of brass), it is 40% stronger than brass, and it is lead free. These Limiters can be moulded in or pressed into the assembly. The precision machined ID tolerance allows proper seating on the core pin when moulding into the assembly. When pressed into the assembly, they are designed with a pilot that allows the part to stand freely in the hole prior to completing the installation. Once installed, the knurl provides excellent retention within the hole. The CL6000 is rated for use up to ISO Class 10.9/Grade 8 bolts.

The CL6000 supersedes the CL600

Brass

The Series CL8000 is machined from 360 brass. Similar to the CL6000, the CL8000 can be moulded in or pressed into an assembly. The applications for SPIROL’s brass and aluminium Compression Limiters are very similar, however to accommodate the same class/grade bolt, the brass Limiters have a larger wall thickness due to the material’s lower yield strength. While this increases the size and weight of the Limiter as compared to the CL6000, the thicker wall does provide more bearing surface for the mating component. The most common reason a designer may choose the CL8000 is for those applications that require a shift away from aluminium on the galvanic series chart to make the Limiter more noble. The CL8000 is rated for use up to ISO Class 10.9/Grade 8 bolts.

The CL8000 supersedes the CL800

Precision Machined Headed Compression Limiters

Headed Aluminium

The CL6100 headed aluminium Compression Limiter is the same as the CL6000, with the addition of a head. The head provides extra bearing surface on the mating component when a flanged bolt or a washer is not used.

The CL6100 supersedes the CL601

Headed Brass

The CL8100 headed brass Compression Limiters are the same as the CL8000 with the addition of a head. Similar to the CL6100, the head provides extra bearing surface on the mating component when a flanged bolt or a washer is not used.

The CL8100 supersedes the CL801

General Purpose Machined Symmetrical Compression Limiters

Aluminium

The CL620 is designed for use in non-critical applications and industries with forgiving assembly requirements. Similar to the CL6000, the CL620 is manufactured from lightweight, lead-free aluminium, offered in a narrower size range with generous tolerances that enable highly efficient manufacturing. For applications that are highly automated with stringent tolerance requirements, or if a headed configuration is required, consider the standard CL6000/CL6100 lines.

Oval Compression Limiters

Split Seam - Oval

Produced from high carbon steel, the oval Series CL400 accommodates 2.25mm extra clearance on one axis, providing additional flexibility over round Compression Limiters for centerline and stack-up tolerancing. Similar to the CL200 and CL350, this split-seam oval Limiter is roll-formed, and it is spring tension that provides positive retention in the hole. The roll-forming manufacturing method yields substantial cost savings over machined products with similar features and characteristics. The CL400 is rated for use up to ISO Class 8.8 bolts.

Additional Compression Limiter Types

Customisable Solutions

If you are unable to find the Compression Limiter in the size, length, material, or finish that you require within our standard offering, or if you are unsure what Compression Limiter is most appropriate for your assembly, Request Engineering Support from our team and we will help you find the most cost-effective solution for your application.

Installation Technology for Compression Limiters

SPIROL offers installation equipment designed specifically for cost-effective and high quality installation of Compression Limiters into your moulded plastic assembly. Our Compression Limiter Installation Equipment range from manual to fully automated machines with statistical process control and error-proofing options. We are the only company of our kind that offers the total integrated solution.

Application Success Stories

Compression Limiters in a Fuel Rail Bracket

Customer Challenge:

A fuel injection systems manufacturer had incorporated the use of two steel brackets to clamp the fuel rail to the top of the engine. As a cost-savings endeavor, they considered using plastic brackets rather than the existing steel brackets. In order to prevent deformation of the plastic brackets during the tightening of the bolts, Compression Limiters would be required.

The manufacturer approached SPIROL to help select the most cost-effective Compression Limiter for their fuel rail assembly.

SPIROL solution:

- SPIROL Engineering recommended the fuel rail manufacturer evaluate the use of SPIROL’s CL200 Split-Seam Compression Limiter based on the rated proof load of the bolt used and the length-to-diameter ratio of the required Limiter for the plastic bracket.

- A roll-formed Compression Limiter manufactured from (non-heat treated) high carbon steel is a fraction of the cost of a machined Compression Limiter.

- In addition, the flexibility of the roll formed Compression Limiter enabled the fuel rail manufacturer to widen their hole tolerance which further reduced the cost of the assembly as compared to the tighter hole tolerance that would be required for a machined Compression Limiter.

- Due to the fact that the manufacturer designed a SPIROL standard CL200 Compression Limiter into their bracket assembly, samples were provided from stock for immediate testing and approval.

- SPIROL's CL200 Split Seam Compression Limiter met the performance expectations of the fuel rail application, and was the most cost effective option compared to other Compression Limiter types.

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+44 1536 444800

USA

USA Canada

Canada United Kingdom

United Kingdom Deutschland

Deutschland México

México Brasil

Brasil France

France España

España 한국

한국 中国

中国