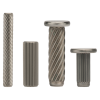

Straight & Dowel Solid Pins

Offered with or without a head, Straight Pins are distinguished by their uniformity. The chamfered ends are more consistent than tumbled edges—making installation with automatic assembly equipment more reliable. Straight Pins are retained by compressing the host, not the inflexible solid pin. They are suitable for use in plastics for press-fit applications limited to those cases where the host material can withstand compression in the order of 0.05mm – 0.08mm (.002” – .003”). Straight Pins are often used to replace Ground Dowels in applications that do not require the tight tolerances of a Ground Dowel.

This White Paper offers more information about the benefits of Cold Headed Pins vs. Machined Solid Pins.

If installation equipment is required, SPIROL also offers a standard comprehensive line of Pin Installation Equipment from manual to fully automatic modules, with or without out fixturing, to support your Solid Pin assembly requirements.

Application Engineering Assistance: If you would like assistance in selecting the proper Solid Pin - including the recommended hole size, tolerance and installation method - please Request Engineering Support! We are here to help!

Straight Pin Product Offering

SPIROL offers two different types of Straight Pins: Series DP100 Straight Pins and Series FH100 Headed Pins.

Straight Pin

SPIROL's DP100 Straight Pins have smooth outer diameters with no retention features such as knurls or barbs. When used as a press-fit pin, the DP100 Straight Pin is pressed into a hole sized slightly smaller than the diameter of the pin. Interference between the pin and the hole must be limited in order to keep insertion forces within practical limits and to prevent damage to the pin or hole during installation. SPIROL's DP100 Straight Pins are suitable for press fit in host materials that can withstand compression in the order of 0.05mm – 0.08mm (.002” – .003”). The actual recommended hole size for a press-fit depends on the actual host material. It is for this reason that SPIROL Engineering should be consulted for the recommended hole size when DP100 Straight Pins are intended to be press-fit into an assembly. Straight Pins are a great option for applications that do not require the tight tolerances of Machined Solid Pins or Ground Solid Dowels. SPIROL Series DP100 Straight Pin consists of metric diameters ranging from Ø2mm to Ø6mm and inch diameters ranging from Ø.078" (5/64) to Ø.250" (1/4).

Headed Straight Pin

(FH100)SPIROL's FH100 Headed Straight Pin has the same body style as the DP100 Straight Pin, with the addition of a head. A Headed Pin is typically used to provide a positive stop or to retain a thin component to a thicker component within an assembly. FH100 Headed Straight Pins have a flat head, however they are available to order with a round head (RH100) to meet specific application requirements. Similar to the SPIROL Series DP100 Straight Pin offering, SPIROL's Series FH100 Headed Straight Pin is available in metric diameters ranging from Ø2mm to Ø6mm and inch diameters ranging from Ø.078" (5/64) to Ø.250" (1/4).

Additional Solid Pin Types

Customisable Solutions

If you are unable to find the Solid Pin in the diameter, length, material, or finish that you require within our standard offering, or if you are unsure what type of pin is most appropriate for your assembly, Request Engineering Support and we will help you select the most cost-effective solution for your application.

Installation Technology for Pins

In addition to a comprehensive line of engineered components used for joining and assembly, SPIROL also offers a full range of Pin Installation Equipment designed to facilitate cost-effective and high quality assembly of your products. Our installation solutions range from manual machines to fully automated work cells with statistical process control and error-proofing options. We are the only company of our kind that offers the total integrated solution.

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+44 1536 444800

USA

USA Canada

Canada United Kingdom

United Kingdom Deutschland

Deutschland México

México Brasil

Brasil France

France España

España 한국

한국 中国

中国