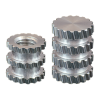

Heat / Ultrasonic

Heat / Ultrasonic Inserts are designed for post-mold installation in thermoplastics. Heat and ultrasonic installation yield outstanding performance results. SPIROL offers several different series of Heat/Ultrasonic Inserts available in a long and short version of each thread size. Long lengths maximize torque and pull-out resistance, while short lengths are good for less stringent requirements at lower cost and shorter installation times. Some styles are available with or without a head. The head provides bearing surface for the mating component that also prevents jack-out (or when used in reverse, can prevent pull through). However, adding a head results in additional cost raw material of a larger diameter is required to create the head. Some non-headed Inserts are symmetrical – thus eliminating the need to orient the Insert prior to installation.

Excellent performance results can be achieved with Heat / Ultrasonic Inserts provided that they are used in the proper hole size with sufficient wall thickness around the Insert and they are installed in a manner that results in proper melting of the plastic to fill the voids of the Insert.

Heat / Ultrasonic Inserts generally provide the best balance between performance and cost.

SPIROL Standard Heat / Ultrasonic Inserts include: Series 14 for tapered holes, Series 19 & 20 for straight holes and Series 29 & 30 for straight holes. SPIROL’s Heat / Ultrasonic Inserts are available in thread sizes ranging from M2 (2-56) up to M8 (5/16-18).

If installation equipment is required, SPIROL also offers a standard comprehensive line of Insert Installation Equipment from manual to fully automatic modules, with or without fixturing, to support your Threaded Insert assembly requirements.

Application Engineering Assistance: If you would like assistance in selecting the proper Threaded Insert for your plastic assembly, please Request Engineering Support! We are here to help!

Heat / Ultrasonic Threaded Inserts Product Listing

Tapered Hole

SPIROL Series 14 Tapered Inserts are designed for use in tapered holes. The tapered hole facilitates proper seating and maximizes the surface contact between the Insert and hole wall prior to the application of heat or ultrasonic vibration. Series 14 Tapered Inserts are available in short and long versions in metric thread sizes ranging from M2 to M8, and unified inch threads ranging from 2-56 to 5/16-18 .

Headed - Straight Hole

Series 19 Straight and Series 20 Headed Inserts have a slightly tapered body designed for use in straight holes to yield excellent performance with low radial stress. Seating and installation are facilitated with a pilot and a tapered knurl and groove design. The Series 20 has the same body style as the Series 19 with the addition of a head to provide additional bearing surface for the mating component to prevent jack-out. Series 19 and Series 20 Inserts are available in short and long versions in metric thread sizes ranging from M2 to M8, and unified inch threads ranging from 2-56 to 5/16-18 .

Symmetrical and Headed - Straight Hole

Series 29 Symmetrical Inserts and Series 30 Headed Inserts are designed with a wide center knurl coupled with two smaller knurls and deep undercuts on both ends to maximize torque and pull out performance. The Series 29 is symmetrical for ease of orientation, and the generous pilot facilitates installation into the hole. The Series 30 has the exact same body style as the Series 29 - with the addition of a head for additional bearing surface for the mating component to prevent jack-out. Series 29 and Series 30 Inserts are available in short and long versions in metric thread sizes ranging from M2 to M8, and unified inch threads ranging from 2-56 to 5/16-18 .

Additional Threaded Insert Types

Customisable Solutions

If you are unable to find the Threaded Insert in the thread size, length, material, finish or quantity that you require within our standard offering, or if you are unsure what Insert is most appropriate for your plastic assembly, Request Engineering Support and we will help you find the most cost-effective solution for your application.

Installation Technology for Threaded Inserts

In addition to a comprehensive line of engineered components used for joining and assembly, SPIROL also offers a full range of Installation Equipment for Threaded Inserts for Plastics specifically designed to facilitate cost-effective and high quality assembly of your products. Our installation solutions range from manual machines to fully automated work cells with statistical process control and error-proofing options. We are the only company of our kind that offers the total integrated solution.

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+44 1536 444800

USA

USA Canada

Canada United Kingdom

United Kingdom Deutschland

Deutschland México

México Brasil

Brasil France

France España

España 한국

한국 中国

中国